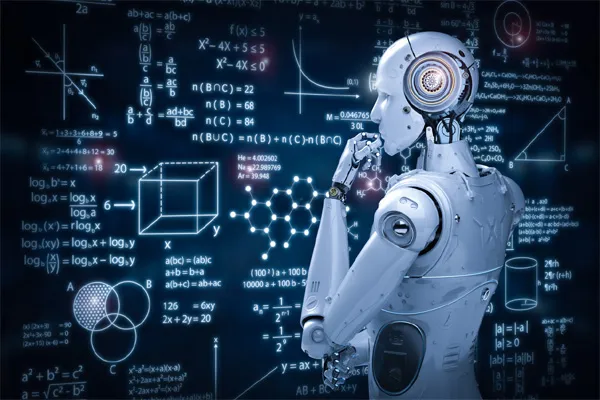

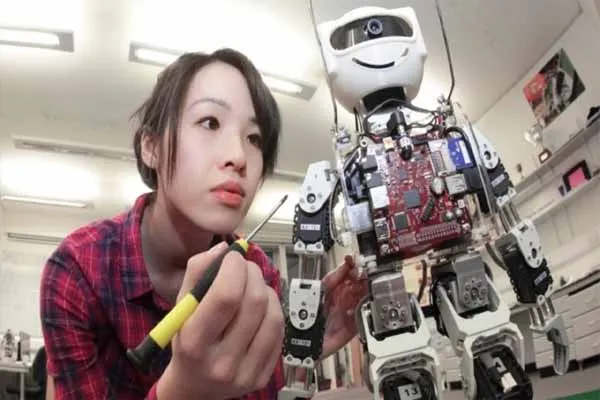

How Robotics Helps AI to Build Machines

The fusion of robotics and artificial intelligence (AI) is revolutionizing the way machines are built and operated. This synergy enhances the capabilities of both fields, leading to more efficient, adaptable, and intelligent machines. Here’s how robotics is helping AI to build machines:

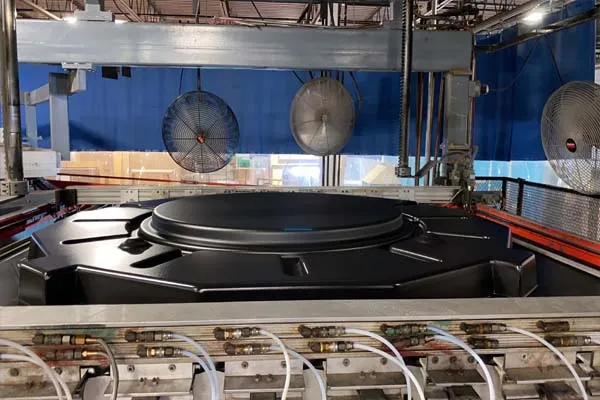

1. Automation of Manufacturing Processes

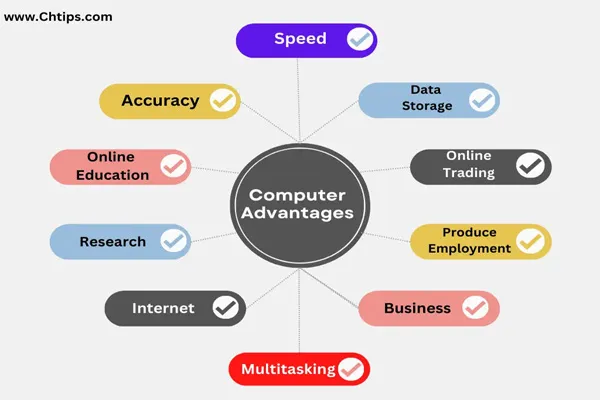

Robotics plays a critical role in automating manufacturing processes. Robotic arms and assembly lines, powered by AI algorithms, can perform repetitive tasks with precision and speed. This not only increases production efficiency but also reduces human error. AI-powered robots can adapt to new tasks quickly, enabling flexible manufacturing systems that can switch between different product lines seamlessly.

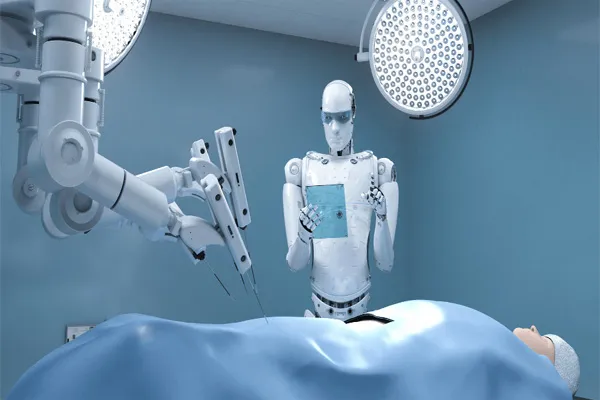

2. Precision and Accuracy

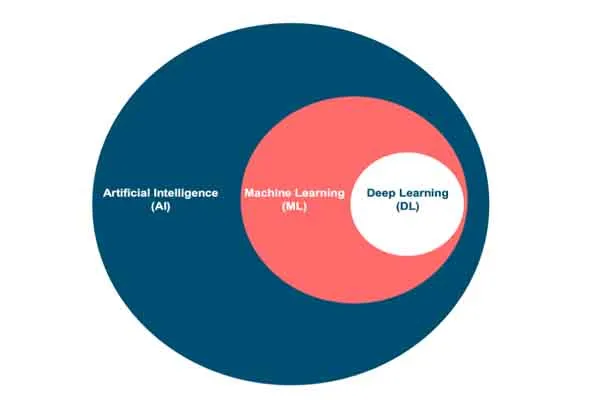

AI-driven robotics brings unparalleled precision and accuracy to the construction of machines. Robots equipped with advanced sensors and machine learning algorithms can perform tasks that require high levels of dexterity and precision, such as assembling microelectronics or performing intricate surgical procedures. This precision is crucial for building high-quality machines that meet stringent industry standards.

3. Enhanced Quality Control

Quality control is a vital aspect of machine building, and AI-powered robots excel in this area. By using computer vision and deep learning, robots can inspect components and finished products for defects at a microscopic level. This ensures that only high-quality machines reach the market, reducing the rate of recalls and enhancing customer satisfaction.

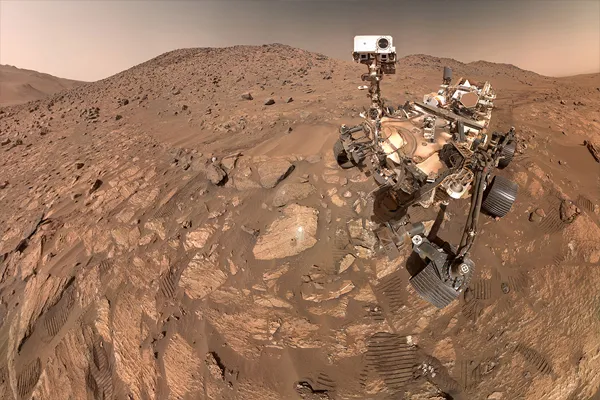

4. Intelligent Maintenance and Repair

AI and robotics enable predictive maintenance, where machines are monitored in real-time to predict and prevent potential failures. Robots can autonomously diagnose issues, perform repairs, and even replace faulty components. This reduces downtime and maintenance costs, ensuring that machines remain operational for longer periods.

5. Collaborative Robots (Cobots)

Collaborative robots, or cobots, work alongside human operators, enhancing their capabilities and improving productivity. Cobots can handle heavy lifting, precise assembly, and dangerous tasks, allowing human workers to focus on more complex and creative aspects of machine building. AI enables cobots to learn from human operators, improving their performance over time.

6. Customization and Personalization

With AI-driven robotics, it is possible to create customized and personalized machines tailored to specific needs. AI algorithms can analyze customer requirements and design machines that meet those specifications. Robotics ensures that these customized machines are built efficiently and accurately, catering to niche markets and individual preferences.

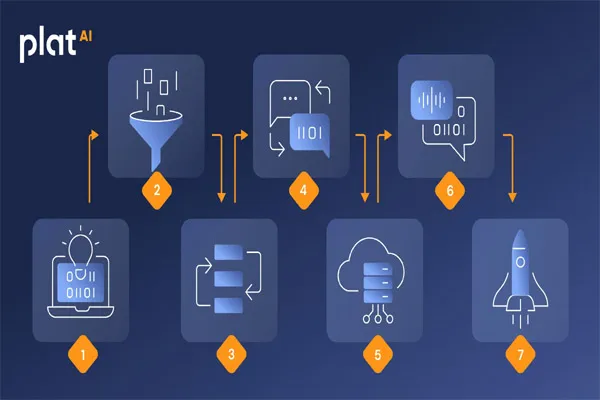

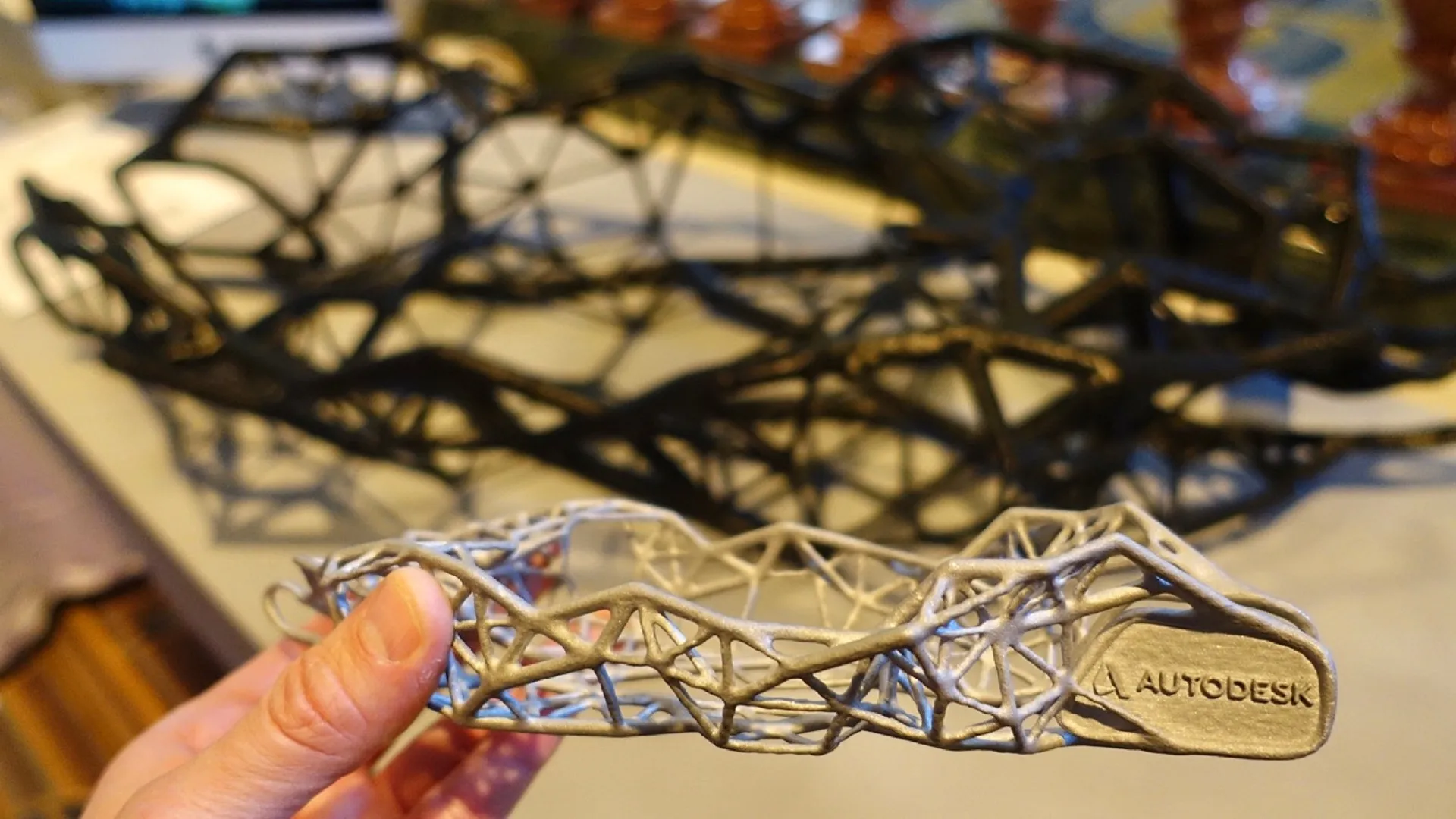

7. Advanced Simulation and Prototyping

AI and robotics facilitate advanced simulation and prototyping. AI algorithms can simulate the performance of a machine before it is built, identifying potential issues and optimizing designs. Robots can then rapidly prototype these designs, allowing for quick iterations and improvements. This accelerates the development process and reduces the time to market for new machines.

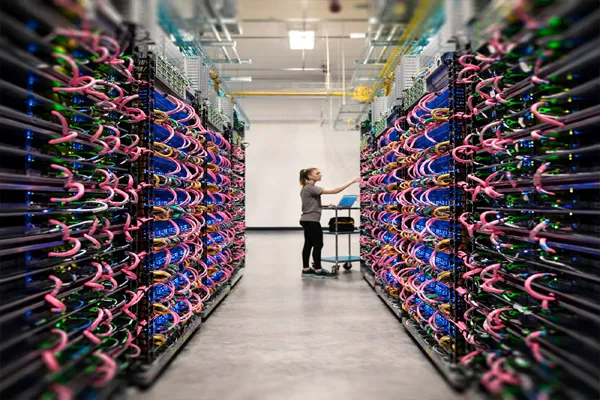

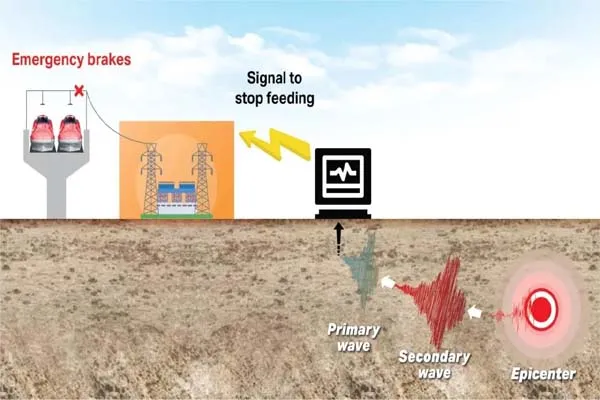

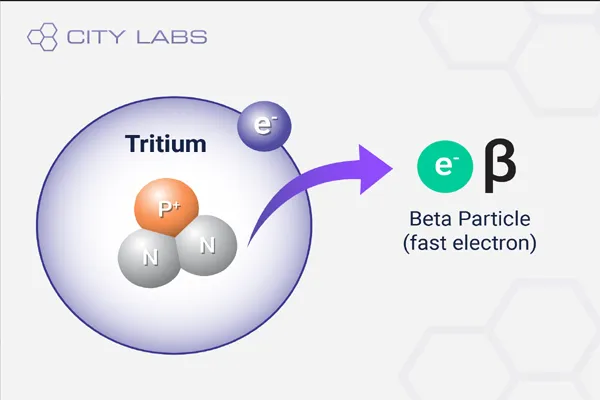

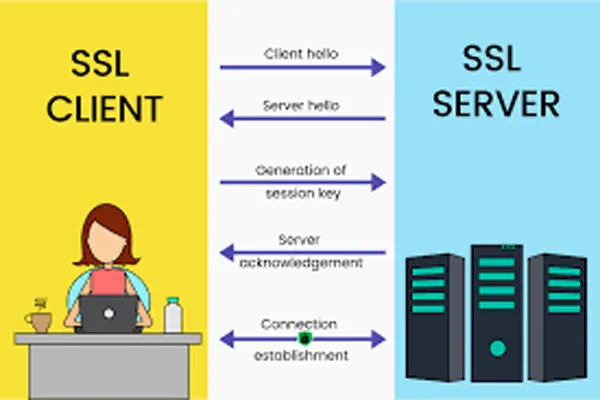

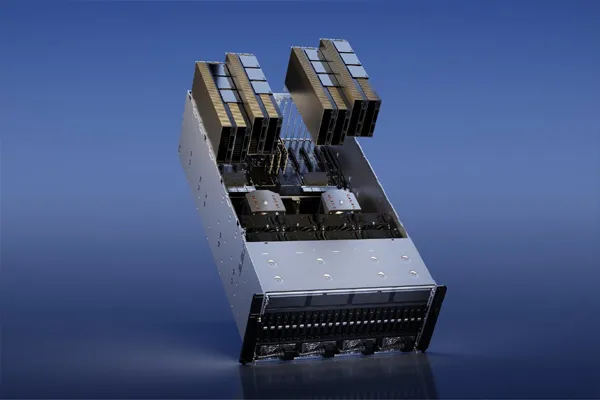

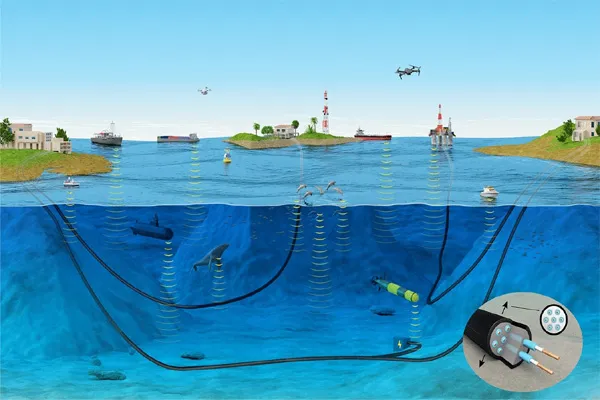

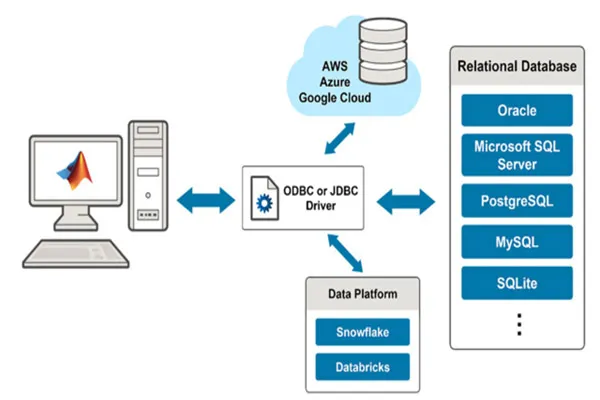

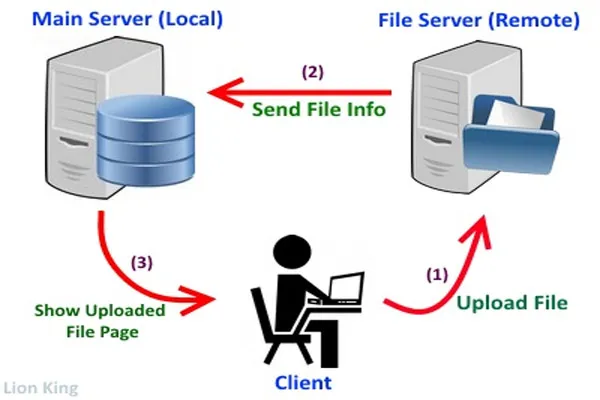

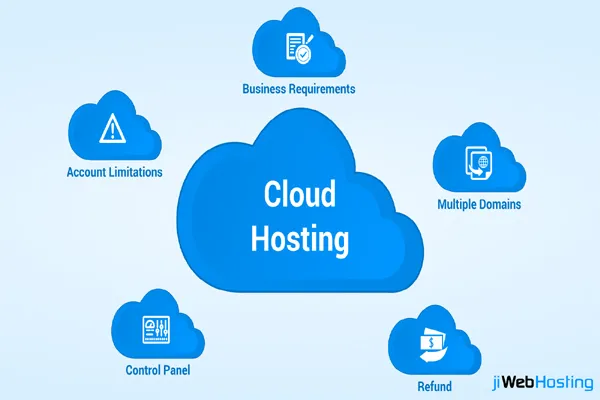

8. Integration of IoT and AI

The Internet of Things (IoT) combined with AI enhances the capabilities of robots in machine building. IoT devices collect data from various sensors embedded in the machines, which AI algorithms analyze to optimize performance, predict maintenance needs, and improve overall efficiency. This integration leads to smarter, more connected machines that can operate autonomously.