Plastics are synthetic materials made from polymers, which are long chains of molecules. Their formation involves several key steps, from raw material extraction to polymerization and processing.

1. Raw Material Extraction

Plastics are primarily derived from petrochemicals, though some modern plastics use renewable sources like corn or sugarcane. The process begins with:

- Fossil Fuels: Crude oil or natural gas is extracted and refined to produce key compounds like naphtha or ethane.

- Bio-based Sources: For bioplastics, plant-based materials (e.g., starch or cellulose) are processed to extract sugars or oils.

2. Cracking and Refining

- Petrochemicals are subjected to a process called cracking, where large hydrocarbon molecules are broken down into smaller ones, such as ethylene and propylene. These are the building blocks (monomers) for most plastics.

- For bio-based plastics, plant materials are fermented or chemically processed to produce similar monomers, like lactic acid for polylactic acid (PLA).

3. Polymerization

Monomers undergo polymerization, a chemical reaction that links them into long chains called polymers. There are two main types:

- Addition Polymerization: Monomers like ethylene bond together without losing atoms, forming plastics like polyethylene (PE) or polypropylene (PP).

- Condensation Polymerization: Monomers bond while releasing byproducts like water, forming plastics like nylon or polyester.

Catalysts, heat, or pressure are often used to control the reaction and determine the polymer’s properties, such as flexibility or strength.

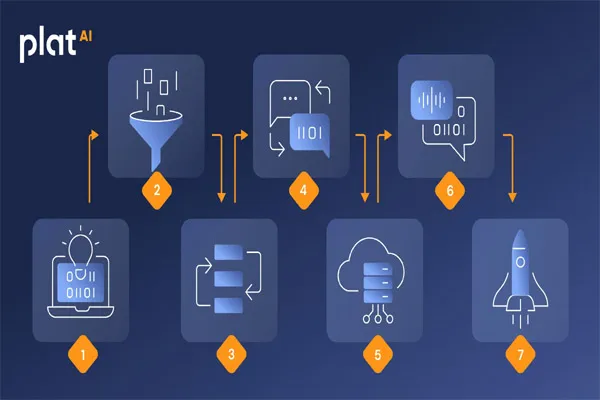

4. Compounding

Polymers are mixed with additives to enhance their properties:

- Plasticizers: Increase flexibility (e.g., in PVC).

- Stabilizers: Improve durability against heat or UV light.

- Fillers: Reduce costs or add strength (e.g., glass fibers).

- Colorants: Add aesthetic appeal.

This step creates a uniform material ready for shaping.

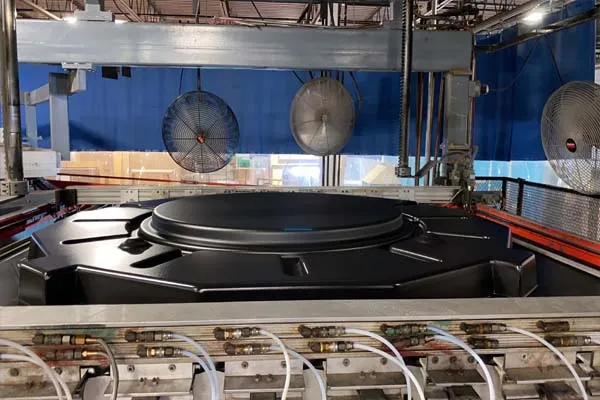

5. Processing and Shaping

The compounded plastic is melted and molded into final products using various techniques:

- Injection Molding: Molten plastic is injected into molds to create precise shapes, like bottles or toys.

- Extrusion: Plastic is pushed through a die to form continuous shapes, like pipes or films.

- Blow Molding: Used for hollow objects, like containers.

- Thermoforming: Heated plastic sheets are shaped into products like packaging.

6. Finishing

After molding, plastics may undergo additional processes like cutting, polishing, or coating to achieve the desired finish or functionality.